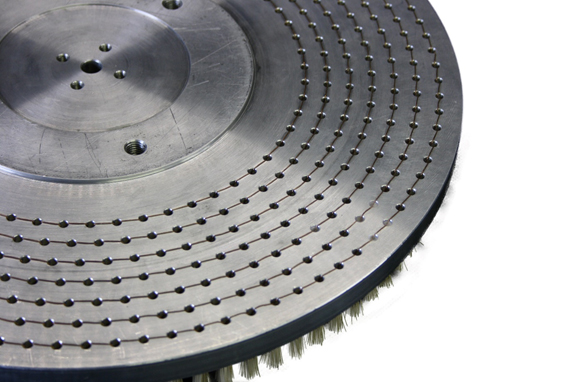

Abrasive

disc brushes

Application

- cleaning

- deburring – ideal for flat surfaces

- rounding of edges

- polishing and finishing

Ideal for

- metals

- plastics

- wood

- glass

- stone

The abrasive disc brushes come in useful in wide range of industrial applications. They are used especially for surface treatment. Mostly for cleaning, deburring, polishing and rounding of edges.

The brushes are fitted with our produced abrasive filaments from aramid (HTF3) or abrasive filaments from PEEK (HTF5). Both material belong among the best synthetic polymer filaments. They are distinguished by high thermal endurance up to 260°C (short-termly up to 300°C), abrasive resistance, elasticity and resistance to wide range of chemical substances.

Thanks to the unique production technology the filaments contain uniformly spread out abrasive particles of synthetic diamonds or SiC, CBN or AL2O3 in the size from #15000 (1µm) up to #36 (470µm).

Advantages

- extended lifetime against nylon brushes

- higher treatment quality

- extreme thermal endurance up to 300° C

- high abrasive resistance

- resistance to most chemical substances

- uniformly spread out abrasive particles – synthetic diamonds, SiC, CBN, AL2O3

- flexible filaments adapting to variously formed workpieces

- replicable polishing results

- suitable for dry and wet applications

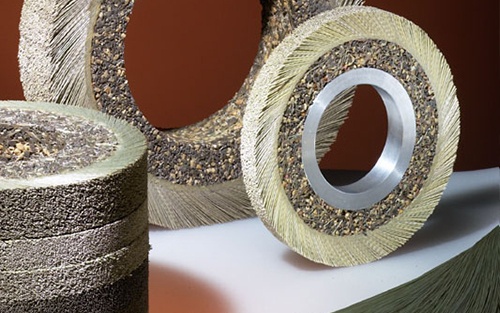

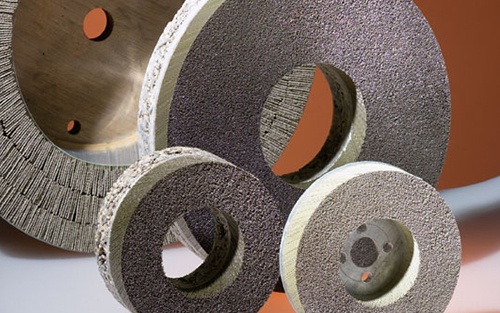

According to the way of production we distinguish the abrasive disc brushes to

- glued abrasive disc brushes

- stapled abrasive disc brushes

- drawn abrasive disc brushes

Glued abrasive disc brushes

They can contain the filaments in the form of segments and little bundles.

The bundle brushes are used by easier deburring operations where the accent is put on short term period of the cycle. They are very flexible and allow to work even in small gaps.

Segment brushes are used for mid-hard to hard deburring operations, rounding of edges and surfacing. Thanks to unique binding way of abrasive particles into the brush filament it comes to extended lifetime and to automatic renewing of the self-sharpening effect of the brush. The bigger filament density leads to faster treatment of the workpiece.

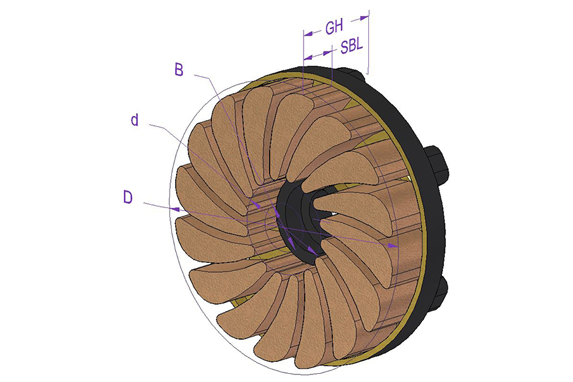

Standard dimension

| D (mm) | 150 | 80 |

| d (mm) | 70 | 40 |

| B (mm) | 22 | 22 |

| SBL (mm) | 16 | 15 |

| GH (mm) | 44,5 | 43,5 |

Maximal brush revolutions: n = 3200 rpm.

Other dimensions on request.

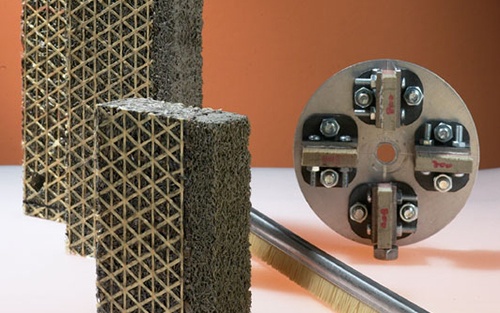

Stapled abrasive disc brushes

The stapled abrasive disc brushes are produced only to order, do not hesitate to contact us with your demand.

Drawn abrasive disc brushes

The drawn abrasive disc brushes are produced only to order, do not hesitate to contact us with your demand.

Abrasive brushes HiT Brush

As fitting material for different types of brushes we use our special filaments.

Standardly we produce brushes